1. POWDER STORAGE

PYRAMIDS uses intelligence Temperature and humidity controlled for powder coating materials…

READ MORE

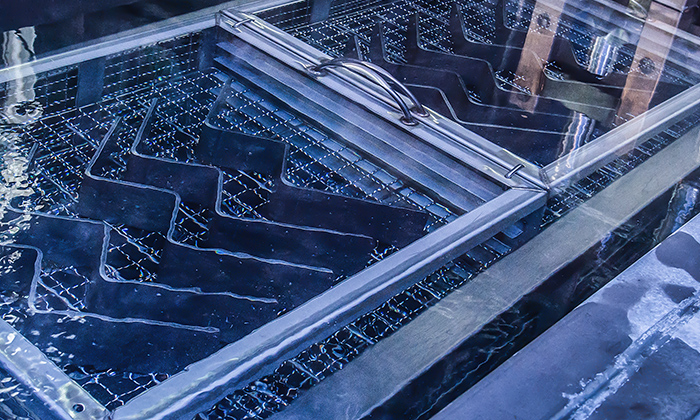

2. PRETREATMENT & CLEANING

PYRAMIDS POWDER COATING uses dipping pretreatment combines all 11 procedures as scald, pre-degreasing, degreasing, acid washing, surface treatment, chemical film, washing, pure water washing, drying…

READ MORE

3. MASKING & HANGING

PYRAMIDS uses high-temperature polyester tape, silicone plugs and caps to mask off certain areas to ensure the integrity surface of the finish and production…

READ MORE

4. SPRAY BOOTH

PYRANIDS equipped with CRS and ZYL powder coating booth with high percentage of powder recycling, rapid color change for diversified colors, efficient, stable and flexible production of high standard criterion…

READ MORE

5. CURING

PYRAMIDS POWDER COATING equipped with Infrared Heating System. Computerize monitor, infrared waves go together with gas catalytic heating. Well finished and uniformed workpieces accomplished with no coating scaling, wrinkles and bubbles…

READ MORE

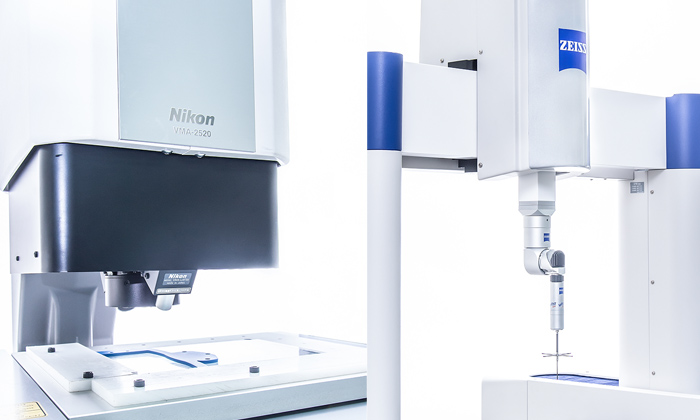

6. QUALITY CONTROL

PYRAMIDS equipped with various professional inspection instrument, strictly scrutinize every chromatic aberration, film thickness, cross-cut adhesion, appearance and major dimensions to verify the highest quality of every well finished products…

READ MORE

7. ECO-FRIENDLY

PYRAMIDS strictly execute four purified steps to pretreatment and paint stripper waste water…

READ MORE

8. HIGHLIGHT

PYRAMIDS dedicates in e-system. From intelligence powder storage, punctual titration, computerize scheduling, powder painting, curing to high standard quality control. We’ve even achieved 97% plus of defect-free rate recently…

READ MORE