Pyramids Quality Policy

Quality assurance and customer satisfaction is what PYRAMIDS always pursuing by continuous development innovations and production improvement. We established a solid quality management system and process including supplier evaluation, incoming quality inspection, in-process quality control, reliability testing of chromatic aberration, film thickness, cross-cut adhesion, appearance and major dimensions to support our production process and standard requirement.

The powder suppliers of PYRAMIDS severely monitor all conditions of film thickness, powder, storage stability, hardening, appearance, coating, particle size, color, gloss, pencil hardness, shock resistance, flexing endurance, adhesive bonding, and chromatic aberration by color palettes and product inspection reports to verify the highest quality of every well finished products.

Pyramids Quality Management System:

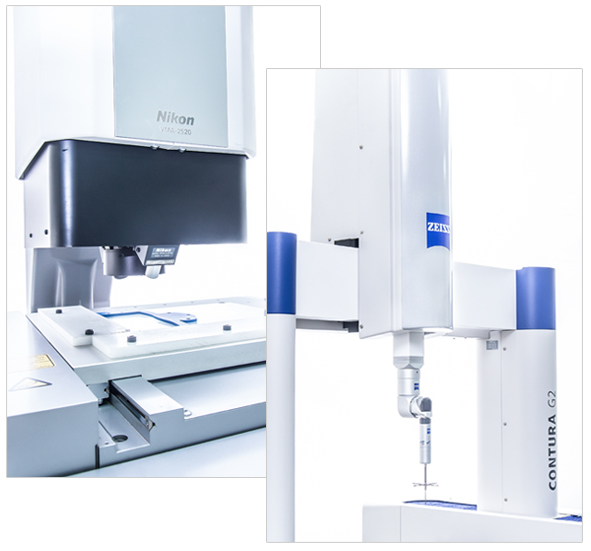

| • ZEISS CMM |

• Nikon 2.5D Optical Comparator |

| • Spectrophotometer |

• Glossmeter |

| • Thickness Tester |

• Elcometer 550 |

| • Mitutoyo Hardness Testers |

• Thread Gauge, Test Fixture, Vernier Calipers |

Pyramids Quality Assurance Testing Plan

| • Inspection system from IQC, IPQC, OQC, and FAI |

| • AQL |

| • Gauge Calibration implementation and management |

| • Reliability control and statistical defect analysis |

| • Professional powder supplier (SHERWIN, PPG, AkzoNobel...) |

| • Periodical staffs training, rating and review |